The secrets of ultrasonic cleaning

Share

In the art of vinyl cleaning, using an ultrasonic system is the method that stands out due to its effectiveness and performance. But you still need to understand how it works and follow a few rules, especially when using a machine that wasn't originally designed for this purpose.

Indeed, machines such as Humminguru, Degritter, Audio Desk, KL Audio, etc. have been specifically designed to clean vinyl records. Apart from the few settings available, everything is done to obtain the best possible result according to the characteristics of the equipment and in complete safety for the media.

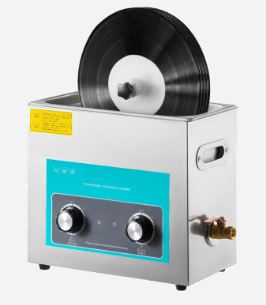

The subject of this article is rather ultrasonic cleaning tanks designed for general use but equipped with a device allowing several discs to be installed and ensure their rotation during the cleaning process. These devices are very generally manufactured in China and can integrate more or less sophisticated functions but no automation. It is up to the person who has invested in this type of equipment to implement the right method to ensure optimal results.

Principle of ultrasonic cleaning

A bit of theory: It involves diffusing a high frequency of several tens of kilohertz into a liquid medium to cause a phenomenon called cavitation. The waves will cause cyclical pressures and depressions in the fluid, thus generating vacuum bubbles. These bubbles then spontaneously implode under the pressure of the water. It is this implosion that will expel a hyper-localized jet of liquid at high pressure onto the surface to be cleaned and which will therefore dislodge the impurities.

What ultrasound frequency?

There is not much choice in reality, the majority of cheap bins use a frequency of around 40 kHz which is sufficient for cleaning vinyl records.

Overall, the higher the frequency, the smaller the cavitation bubbles will be, resulting in precise cleaning but also less energetic. The opposite allows for more efficient cleaning, but on larger particles and will tend to heat the bath more quickly. So it's a matter of compromise!

In any case, avoid frequencies that are too low (< 40 kHz) which are rather reserved for cleaning coarse mechanical parts.

Bath composition

Use demineralized water, never tap water, which is too high in minerals. This water will prevent the sandblasting effect on the record and will not leave a mineral charge when drying once the record is cleaned. The addition of a surfactant provides additional effectiveness by increasing the fluidity of the water, that is, by allowing the water to penetrate deep into the groove (reducing the surface tension of the fluid). You can use our Concentrated Vinyl Cleaner product for this, which is a mixture of two types of Tergitol that significantly improves cleaning. This is the product we use at Record Clinic during the Cleaning stage of our Premium process. This high-performance surfactant is popular with archiving professionals and audiophiles due to its very low sound signature and its effectiveness. Rinsing is not necessary if the recommended dosage is respected (2 drops per liter of solution).

Pure alcohol such as Isopropanol (IPA) at 99.9% or higher can also be added for its degreasing properties, but in modest proportions. We recommend not exceeding 2.5% for safety and efficiency reasons (a higher level does not improve cleaning). Be careful, always dilute the surfactant well in the solution before adding the IPA (risk of "lumps" forming).

Avoid using dishwashing detergent or modified alcohols that contain other undesirable components such as perfume, dye, glycerin or other fatty products.

Preparing the bath

Before proceeding with the first cleaning, it is important to degas the cleaning fluid. The idea is to remove all the gases dissolved in the water to improve cleaning efficiency. Indeed, some of the ultrasound energy will be captured by the bath itself, reducing the action on the objects to be cleaned. If your device operates at a frequency of 40 kHz, run the degassing for approximately 20 minutes. At 80 kHz, 5 minutes is sufficient.

If your device does not have this function, wash a first batch of discs and start again a second time. The first pass will allow the bath to degas, the second will allow your discs to be effectively cleaned. Never run an ultrasonic machine empty!

Cleaning duration

There's no need to leave your records in your ultrasonic cleaner for too long: given the characteristics of a vinyl record and the depth of the groove, 2 minutes is enough to remove all contaminants. Exposure for longer will not improve cleaning and may cause the cleaner to heat up unnecessarily.

Since approximately 1/3 of the surface is immersed in the bath (water level under the sticker), a 6-minute cycle will be enough to ensure proper cleaning of your vinyl records rotating in your machine.

Rotation speed

If possible, set your motor to the lowest possible speed. Ideally, you should spin your discs once or twice in a 6-minute cycle. By reducing the speed, you reduce the water current (wake caused by the disc moving in the bath) on the surface of the disc, which reduces the effectiveness of the ultrasound. This will allow time for the cavitation phenomenon to work effectively on the soiled parts.

Separate your discs with the correct distance

This is an important parameter because an ultrasonic machine uses pressure waves whose wavelength depends on the frequency. In the case of cleaning several discs simultaneously, this spacing must therefore allow an identical distribution of energy on each object. The ideal seems to be around 20 mm for a tank operating at 40 kHz.

Monitor the bath temperature

Many standard ultrasonic cleaners are equipped with a heating mechanism. While this is very useful for heat-resistant objects to increase cleaning efficiency, excessively hot water is extremely dangerous for your record, causing warping. Avoid using this device at all costs!

You should never exceed a temperature of 30°C for the bath, otherwise your records may be damaged. We recommend a temperature between 25°C and 28°C for safe cleaning.

Change the bath regularly

Particles and other contaminants that are extracted from the cleaned records remain suspended in the cleaning bath. After a certain number of cycles, this solution will become too loaded and will considerably reduce the cleaning efficiency, or even contaminate your records instead of cleaning them. We recommend renewing the solution at most every 8 cycles, but this depends on the number of records cleaned simultaneously and especially on their dirtiness. In any case, you do not clean microgroove records with dirty water! We also do not recommend reusing a solution after filtration, even very fine, because many microparticles will remain in suspension, as well as grease, soot, tar, and other contaminants in liquid form. Similarly, do not keep your bath for too long, at most 5/7 days, because microorganisms (bacteria) will eventually develop there.

You now know the main parameters to follow when cleaning your records yourself using ultrasound. Remember that this technique is reserved for vinyl records. 78 rpm and direct-burning records (Acetates, Pyral) are very sensitive to humidity, should not be exposed to alcohol, and are fragile, so you risk irreparably destroying them.